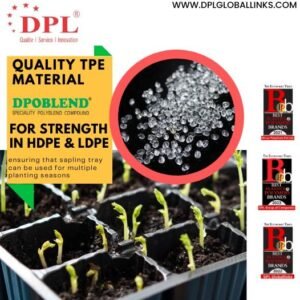

Discover how DPL Group enhances HDPE and LDPE performances with DPL Thermoplastic Elastomers (TPE). Explore the synergy between these materials, boosting strength, flexibility, and durability for diverse applications in automotive, packaging, agriculture products etc. DPL Group sets the industry standard for TPE excellence.

Plastics have become ubiquitous in our lives, finding applications in various industries, from packaging and construction to automotive and healthcare. Among the numerous plastic materials available, High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) are two common choices. They offer a range of desirable properties, but what if we told you there’s a way to enhance their performance further?

Enter Thermoplastic Elastomers, or TPEs for short. These versatile materials have gained recognition for their unique ability to augment the strength, flexibility, and durability of HDPE and LDPE. In this article, we’ll delve into the fascinating world of TPE and explore how it can elevate the performance of these plastics.

Understanding HDPE, LDPE, and TPE

Before we dive into the synergy between TPE and HDPE/LDPE, let’s briefly understand these materials:

- HDPE (High-Density Polyethylene): HDPE is known for its exceptional strength, chemical resistance, and suitability for applications requiring robust, rigid plastics. It’s commonly used in pipes, bottles, and various structural components.

- LDPE (Low-Density Polyethylene): LDPE, on the other hand, is more flexible and less dense than HDPE. It excels in applications requiring pliability, such as plastic bags, squeeze bottles, and agricultural films.

- TPE (Thermoplastic Elastomer): TPE is a class of materials that combines the properties of traditional thermoplastics (like HDPE and LDPE) with those of elastomers (like rubber). TPEs are known for their flexibility, resilience, and ease of processing.

The Magic of TPE in HDPE and LDPE

Now, let’s explore how TPE can work its magic when incorporated into HDPE and LDPE:

- Strength Enhancement: HDPE and LDPE are strong materials on their own, but by blending them with TPE, you can significantly enhance their tensile strength. TPE’s unique molecular structure contributes to improved rigidity, making the resulting composite material better suited for load-bearing applications.

- Flexibility and Durability: LDPE is renowned for its flexibility, and TPE takes this property a step further. When combined, they create a material that’s not only flexible but also exceptionally durable. This blend is ideal for products that require both resilience and strength, such as medical tubing or flexible packaging.

- Impact Resistance: TPE’s elastomeric properties impart excellent impact resistance to HDPE and LDPE composites. This is a game-changer for industries like automotive and construction, where impact protection is crucial.

- Ease of Processing: TPEs are highly versatile and can be easily processed using conventional thermoplastic methods. This makes it convenient for manufacturers to integrate TPE into their existing production processes.

- Chemical Resistance: HDPE and LDPE are known for their chemical resistance, and the addition of TPE does not compromise this property. The resulting composite remains resilient in the face of various chemicals, ensuring longevity in harsh environments.

Applications of TPE-Enhanced HDPE and LDPE

The possibilities for TPE-enhanced HDPE and LDPE are vast. Some notable applications include:

- Automotive Components: TPE-enhanced HDPE/LDPE can be used in interior components, gaskets, and under-the-hood parts, where flexibility and durability are critical.

- Medical Devices: The combination of flexibility and strength makes TPE-infused LDPE suitable for medical tubing, syringe components, and more.

- Packaging Solutions: Flexible and tough TPE-enhanced LDPE is perfect for creating robust yet pliable packaging materials.

- Construction Materials: TPE-enhanced HDPE is an excellent choice for construction materials like pipes, profiles, and sheets, offering enhanced impact resistance and durability.

TPEs have revolutionized the world of plastics by enhancing the performance of HDPE and LDPE. These versatile materials offer manufacturers the opportunity to create products that are not just strong and durable but also flexible and resilient. Whether in the automotive, medical, packaging, or construction industry, the incorporation of TPE opens doors to new possibilities and improved product performance. As technology continues to advance, we can expect even more innovative applications of this dynamic trio.

DPL Group of Companies proudly stands as a leading manufacturer of the highest quality TPE solutions tailored specifically for HDPE and LDPE applications. With a commitment to excellence, DPL Group ensures that their TPE materials not only meet but exceed industry standards, setting a benchmark for strength, flexibility, durability, and overall performance.

Contact us to know more:

https://dplgloballinks.com/contact/